06-09/2023

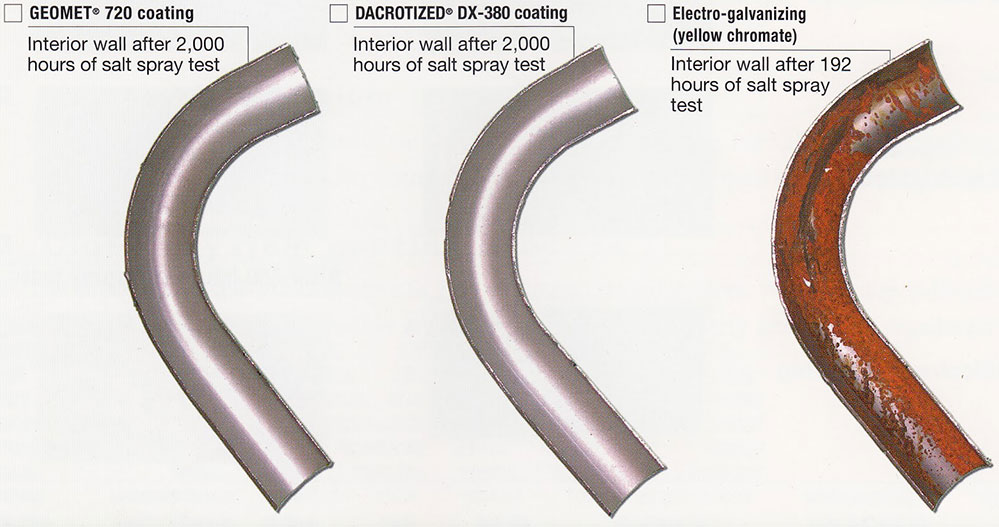

While the three metals offer increased durability, they do not have the same degree of machinability. You should consider this to ensure smoother machining and cost reduction.Budget is another crucial consideration. Brass is the cheapest of the three metals, while copper is the most expensive. Therefore, if budget is a concern, you may want to go for brass.Ultimately, application and utility also come to play in your selection. The eventual use of your component will determine the type of metal you choose. Copper will be beneficial whenever you need electrical conductivity. Bronze s suited for saltwater applications because of its corrosion resistance. It is also durable and hard, and it can withstand fatigue.