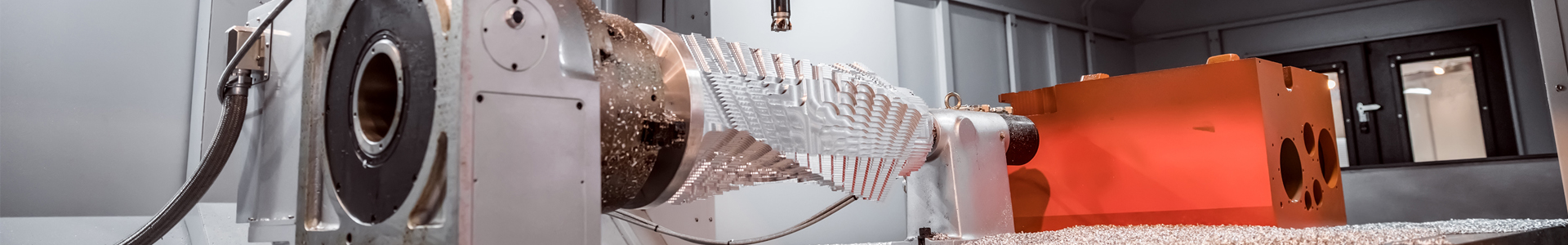

Anodizing is a popular process with a range of applications in industries such as construction, automotive, and aerospace. It is an effective way to improve the performance and aesthetics of metal objects especially aluminum. It is an electrochemical process that involves creating an oxide layer on the surface of a metal object. This process is commonly used to increase the durability and corrosion resistance of metals such as aluminum. Now let's exploring more basic guide about anodizing.

Definition of Anodizing

Anodizing is a surface treatment process that involves creating a layer of oxide on the surface of a metal part, typically aluminum. The process involves immersing the aluminum part in an electrolyte solution and applying an electric current to the part.

Main Types

Type I Anodizing (Chromic Acid Anodizing): This type of anodizing uses chromic acid as the electrolyte. It produces a thin and non-porous oxide layer that provides good corrosion resistance. Type I anodizing is used mainly in the aerospace industry for coating parts that require electrical insulation and protection against corrosion.

Type II Anodizing (Sulfuric Acid Anodizing): This is the most common type of anodizing, which uses sulfuric acid as the electrolyte. It produces a thicker and more porous oxide layer compared to Type I anodizing. The thickness of the layer can be controlled and varied by changing the processing conditions such as voltage, current density, temperature and time. Type II anodizing increases resistance to wear and corrosion and facilitates dyeing processes for decorative applications.

Type III Anodizing (Hard Anodizing): Also known as Hardcoat anodizing, this process uses a different electrolyte of higher acidity and lower temperature conditions compared with Type II. It produces a thicker and denser oxide layer which is harder and more abrasion resistant. Type III Anodizing is utilized primarily in industries requiring greater wear resistance, improved hardness or color options such as tooling, medical industry, automotive and aerospace parts.

Anodizing: Pros And Cons

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of metals, particularly aluminum. Here are some pros and cons of anodizing:

Pros:

Durability: Anodized surfaces are harder, more durable, and resistant to wear and corrosion than untreated metal. The anodized coating also makes the metal more scratch-resistant.

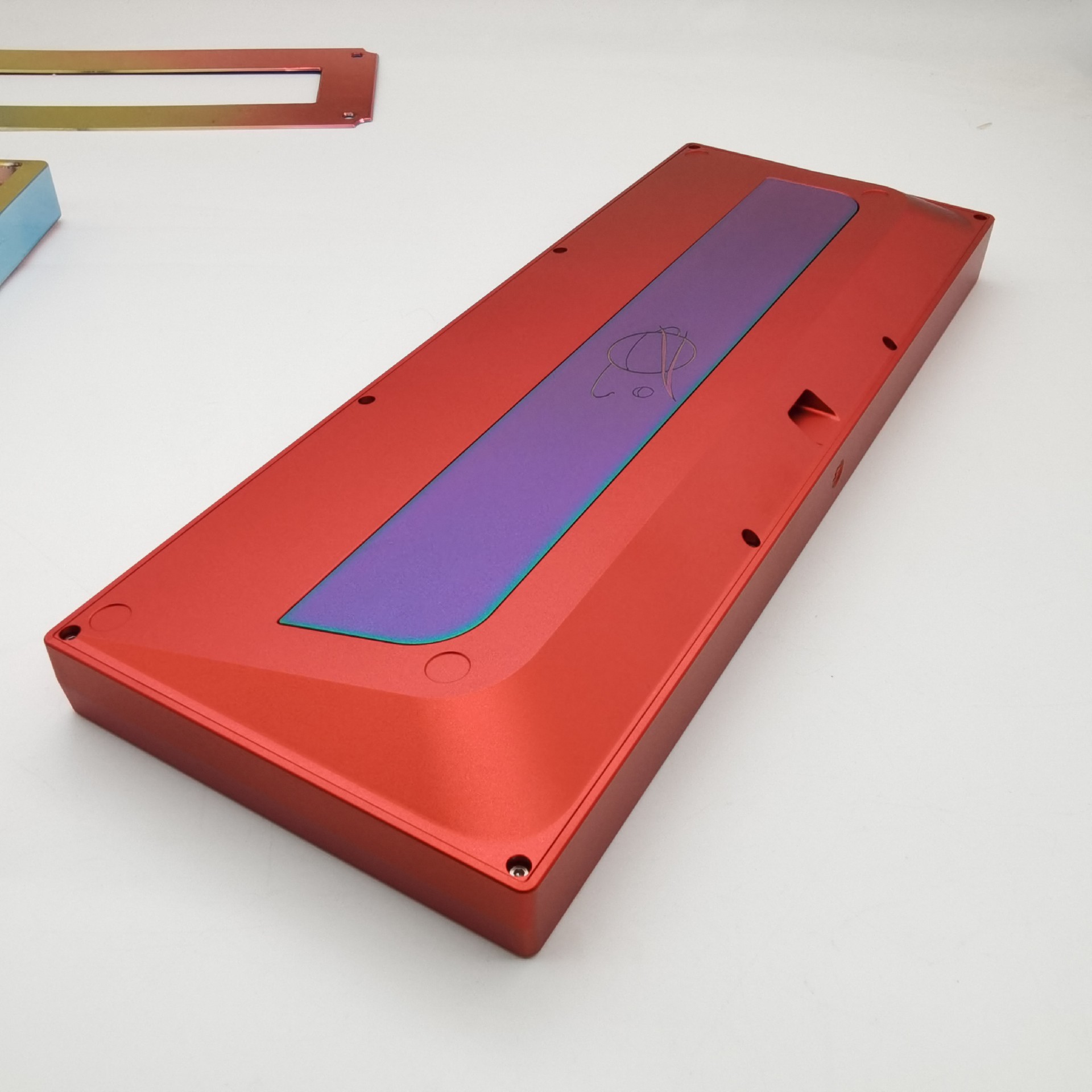

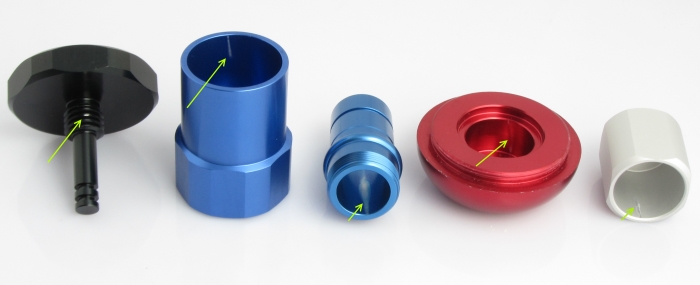

Aesthetic appeal: Anodizing can be used to create unique and vibrant colors as well as matte or glossy finishes. It can provide a decorative and attractive appearance to metal surfaces.

Environmental concerns: Anodizing is a more environmentally friendly option than other processes like plating because it doesn't produce any harmful waste or emissions.

Increased lifespan: Anodized parts have a longer lifespan compared to untreated parts due to improved resistance to oxidation and corrosion.

Cons:

Complexity: Anodizing process requires significant preparation and careful monitoring to achieve consistent results. If the process is not performed correctly, the results could be unpredictable.

Cost: Anodizing can be significantly more expensive than some other surface finishing options, such as powder coating or painting.

Limited application to certain metals: While anodizing works very well for aluminum, it may not work well with other metals like steel and copper.

Potential for mechanical failure: Despite the durability of anodized surfaces, over time, heavy use or exposure to intense mechanical stresses might potentially cause mechanical failure or cracking of the coating.

Design Tips For Anodizing Aluminum

Avoid sharp edges and corners: Sharp edges and corners can result in uneven coatings that may look blotchy or corrode more easily over time. Rounded edges and corners provide better results and durability.

Watch Out for Tolerances: If you know you want to apply the anodizing process to your aluminum component, be aware that the process does add some thickness to the part. This is because it can (albeit marginally) affect part tolerances. If tight tolerances are critical, consider the option for Type I or Type II anodizing. You can also take the extra layer into account in the design stage.

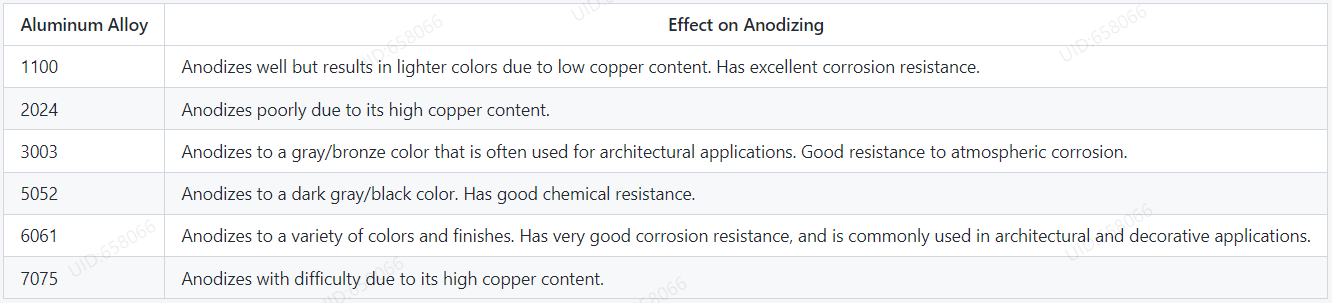

Choose the right alloy: Different alloys of aluminum anodize differently, so it's essential to consider the specific properties needed for the project and choose the appropriate alloy.

Allow for enough surface area for an even coating: The size and shape of the part being anodized should offer enough surface area to allow the electrolyte solution to distribute evenly over the surface.

Consider the color options: Anodized aluminum comes in different colors, but not all dyes work with all alloys, so it is important to choose the right dye that suits the job before transforming your design into production.

Work With Batches:If you are coloring your aluminum parts or products, it is advisable to anodize them in small batches. This ensures a greater degree of color uniformity, as it can be difficult to exactly match a color from one batch to the next. The ideal scenario for color consistency is to anodize a small batch of small parts at once.

Consider Using Othere Finishing Steps: Anodizing is an electrochemical process. Therefore, it doesn't have the same effect as shot blasting (aslo called beat blasting or sand blasting) or polishing. If an aluminum machined part goes straight to anodizing, some machine marks or scratches will likely remain on the finished part's surface.

For this reason, if you require a completely uniform surface finish, it can be beneficial to use polishing, bead blasting or another mechanical finishing process beforehand. Anodizing will make the surface of a part smoother than before.

By following these design tips, you can achieve optimal results when anodizing aluminum parts, creating stunning and durable finishes ideal for a range of applications in various industries.

Shot Blasting Before Anodizing Parts

Shot blasting is a mechanical surface treatment process that involves propelling abrasive materials at high velocity to remove impurities or prepare a metal surface for further processing. It can be done before anodizing to improve the quality and adhesion of the oxide layer.

Shot blasting creates a roughened surface on the metal that enhances the anchorage between the aluminum surface and the anodic oxide layer. The roughening also provides a uniform substrate for the oxide layer to grow, resulting in a more uniform and consistent surface finish. Thus, shot blasting helps to ensure that the anodic oxide layer adheres well to the aluminum surface, providing better durability and corrosion resistance.

In addition to improving adhesion and consistency, shot blasting also removes impurities from the metal surface, including paint, oil, rust, and other contaminants. This can help to prevent defects such as staining or etching during the anodizing process.

Overall, shot blasting can be an effective pre-treatment step for anodizing, especially when dealing with parts that have a pitted or rough surface. However, it requires expertise to ensure that the shot blasting process does not damage the parts and promote residual stresses leading to warpage during anodizing. It's essential to consult with experienced professionals before deciding whether shot blasting is necessary and the best option for a particular project.

Different Aluminum Alloys And Its Affect On Anodizing

There are various aluminum alloys with different compositions, the composition of an aluminum alloy has a direct effect on its ability to be anodized and resulting color and finish.

The two most commonly used aluminum alloys for anodizing are 6061 and 5052.

Understanding Racking Marks In Anodizing

Rack marks and racking marks refer to the marks or lines that can be left on the surface of a metal part during anodizing.

During the anodizing process, metal parts are suspended from racks or hooks to ensure even coating. These racks can leave small marks or lines on the surface of the part where they come into contact with it.

While rack marks are usually visible but not critical, racking marks are more severe, and they can weaken the metal's integrity. These marks occur when a part experiences excessive pressure against the rack, causing the material to bend or even break.

Preventing rack and racking marks is essential for producing high-quality anodized parts. Technicians can use a combination of proper racking techniques, padding, and surface preparation to minimize or eliminate these marks. It is also important to inspect the part's surface carefully before and after anodizing to identify any defects or blemishes that may have occurred during the process.

Industries Served

Anodizing finds application in various industries such as automotive, aerospace, architectural, electronic, military, and medical among others where the metal components need to withstand harsh environmental conditions and require corrosion-resistance properties. For instance, anodized coatings find application on aluminum parts used in aircraft manufacturing due to its lightweight and strength properties to help reduce the overall aircraft weight. In the architectural industry, Anodized metals are commonly used on building facades where it enhances durability, improves scratch resistance and offers excellent corrosion protection in the face of weathering.

CNCMECHA specializes in custom CNC machining parts made out of various materials. INQUIRY NOW

Available surface treatments

Thanks for reading!

by Karen Xia