Surface roughness is an essential aspect of any manufacturing process either CNC machining, extrusion, or casting, which lies in its ability to impact the performance and functionality of a part. A well-finished surface can improve the durability of a part, increase its resistance to corrosion, reduce friction, extend the part's lifespan, and enhance its aesthetic appeal. Surface finish also has a crucial role in ensuring proper fit and alignment when parts are assembled together.

The surface finish contributes to the overall quality of a product and plays a major role in determining its value. Improved surface finishes can lead to higher selling prices for manufacturers and offer customers a sense of assurance in the reliability and performance of the product.

Achieving the appropriate surface finish is critical to the success of any manufacturing operation, since it can impact everything from product quality and performance to customer demand and the bottom line. Let's develop more about it in this article.

Definition: What is Surface Finish?

Surface finish refers to the texture, roughness, and overall quality of a material's surface after processing or manufacturing. It is an important factor in determining the appearance, durability, and functionality of a product, particularly in industries such as manufacturing, automotive, aerospace, and medical devices. The roughness value can vary depending on the manufacturing process used to create the object and can be measured using different parameters like Ra, Rz, Rq, etc., and is typically achieved through processes such as grinding, polishing, buffing, sandblasting, or chemical treatments. A higher-quality Surface Finish can result in improved performance, reduced wear and tear, enhanced corrosion resistance, and a more aesthetically pleasing appearance.

Main Characteristics Consist Surface Finish

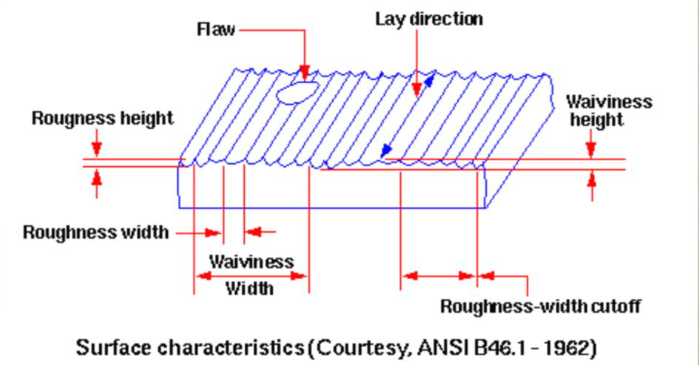

Surface finish refers to the texture and roughness of a solid surface. It consists of various characteristics such as:

Roughness: is the measure of the deviations in the surface pattern from the ideal flat surface. The greater the roughness, the higher the number of irregularities and bumps on the surface.

Waviness: is the deviation of the surface from its expected shape over longer wavelengths. It is often caused by uneven material buildup or damaged tooling.

Lay: This property refers to the direction of the predominant surface pattern, which may be due to machining, polishing or grinding.

Why is Surface Finish Important in Engineering Processes?

Achieving the right surface finish is essential in engineering processes due to its impact on aesthetics, functionality, wear resistance, dimensional accuracy, and cleanliness.

Different surface finishes have a variety of effects. The easiest way to get the desired surface finish is to compare it with the surface finish standards. Surface finish can help in the following ways and more:

Incredibly important for corrosion and chemical resistant effects.

It offers a specific visual appeal to the product.

Helps with the adhesion of coatings and paints.

Eliminates surface defects.

Improves conductivity and adds surface electrical conductions.

Increases product's strength against wear while minimizing friction effects.

To learn more about surface finishing, read our guide to machined surface finish options and read our article about getting the best CNC machining surface finish for your products.

Surface Roughness Chart Symbols and Abbreviations

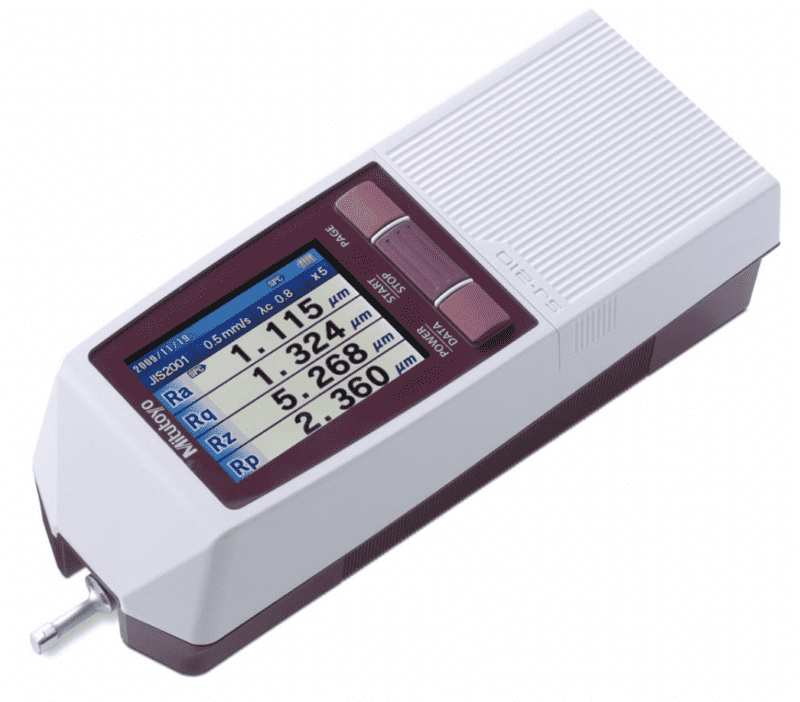

When you search for machining surface finish symbols on your favorite browser, you would notice a range of abbreviations. These include Ra, Rsk, Rq, Rku, Rz, and more. They are units used in measuring surface finish. Ra, Rz, Rmax are the most widely used.

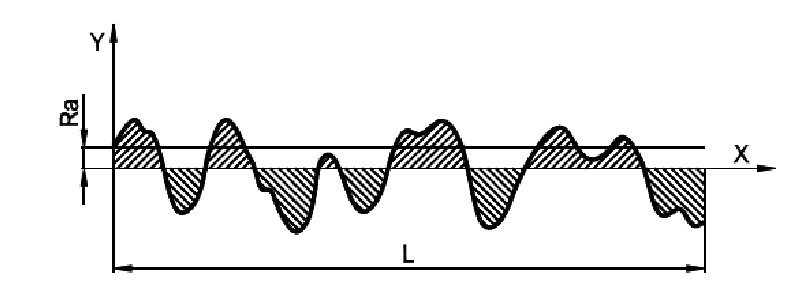

Ra – Average Surface Roughness

While most people refer to Ra as Center Line Average or Arithmetic Average, it is the average roughness between a roughness profile and the mean line. This is the most commonly used parameter for surface finish. The Ra surface finish chart is also one of the most used for absolute values.

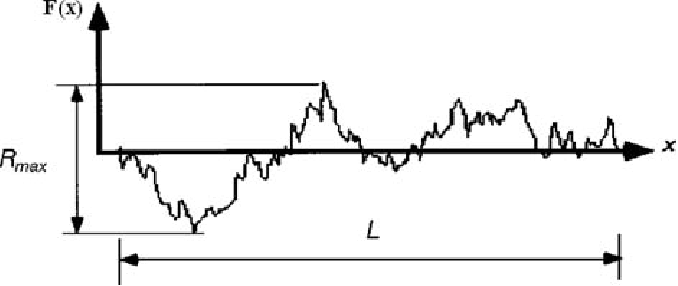

Rmax – Vertical Distance from Peak to Valley

This roughness parameter is best used for anomalies such as burrs and scratches. It may not be obvious with the Ra surface finish chart though. However, Rmax is a lot more sensitive to those anomalies.

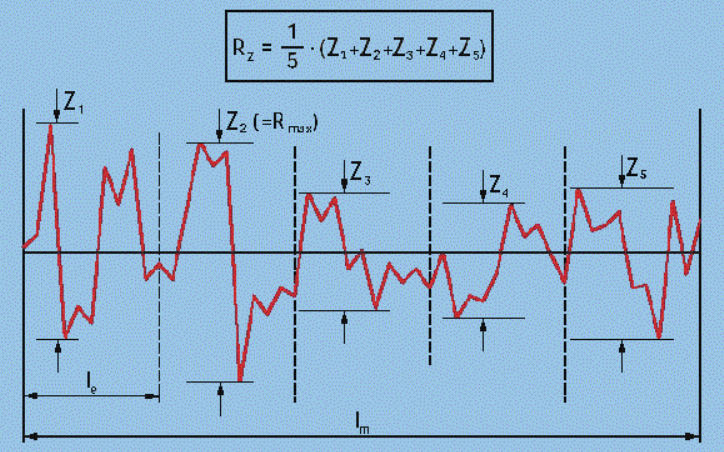

Rz – Average Maximum Height of the Profile

Unlike Ra, Rz measures the average values of the five largest differences between peaks and valleys. The measurement is done using five sampling lengths, and it helps to eliminate error since Ra is quite insensitive to some extremes.

Symbols frequently used in engineering drawings.

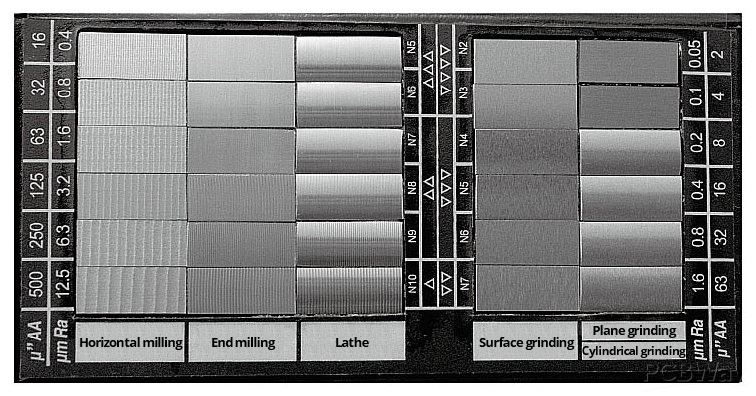

Surface Roughness Chart

Machining surface

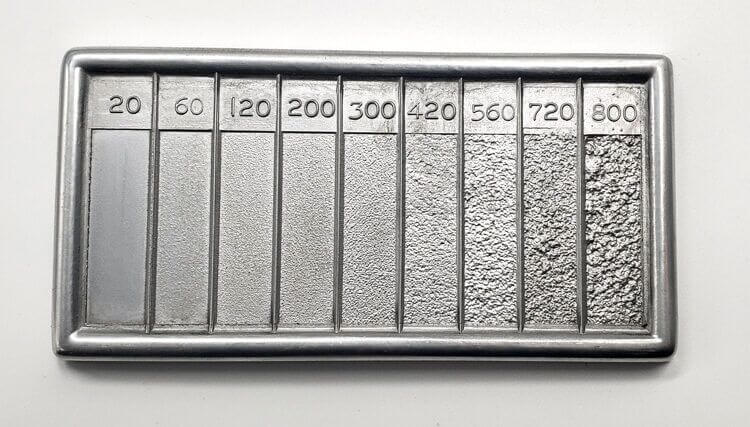

Casting surface

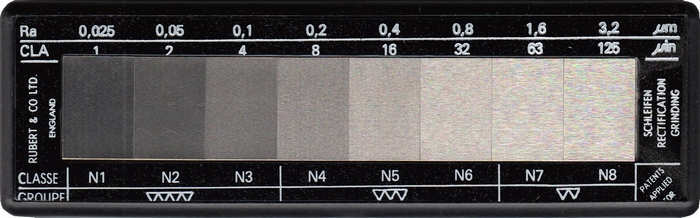

Grinding surface

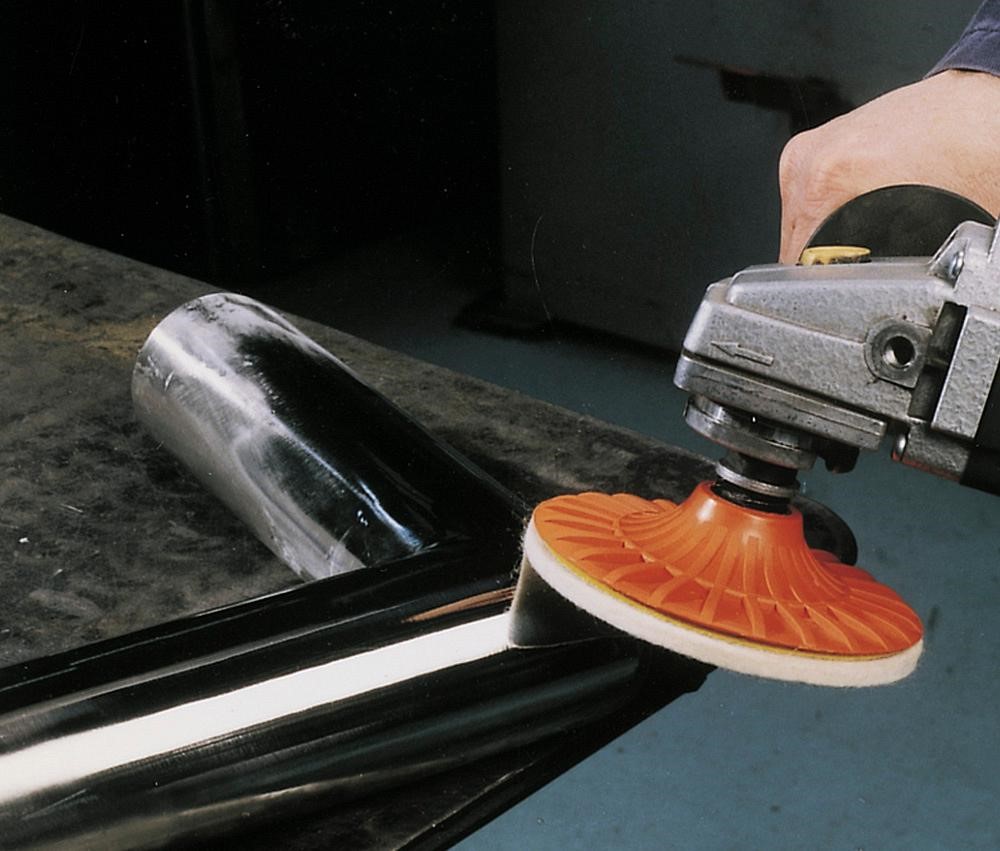

Polishing surface

Cost of surface roughness

Surface roughness can have various costs, depending on the specific application or industry involved. Some potential costs of surface roughness include:

Increased friction and wear: When two surfaces come into contact, any irregularities on the surface can increase friction and wear. This can lead to shorter equipment lifespan and increased maintenance costs.

Reduced efficiency: In some industries, rough surfaces can reduce the efficiency of the production process. For example, a rough surface on a conveyor belt can cause products to snag or not move smoothly, slowing down the production line.

Quality issues: If a product requires a smooth surface for aesthetic or functional purposes, surface roughness can impact its quality. Smoothness may be particularly important in medical applications, where rough surfaces can harbor bacteria.

Processing costs: Surface roughness may need to be reduced before certain processes can occur, such as painting or coating. This can add extra processing steps and cost.

Increased inspection costs: If quality control measures detect surface roughness as unacceptable, additional inspection costs may be incurred to ensure that the surface meets requirements.

Overall, the cost of surface roughness is highly dependent on the context in which it occurs. While some industries may see slight increases in cost due to surface roughness, others may experience significant impacts on efficiency or safety.

To speak to us regarding what might be best for your project and arrange a quote, get in touch with CNCMECHA today.

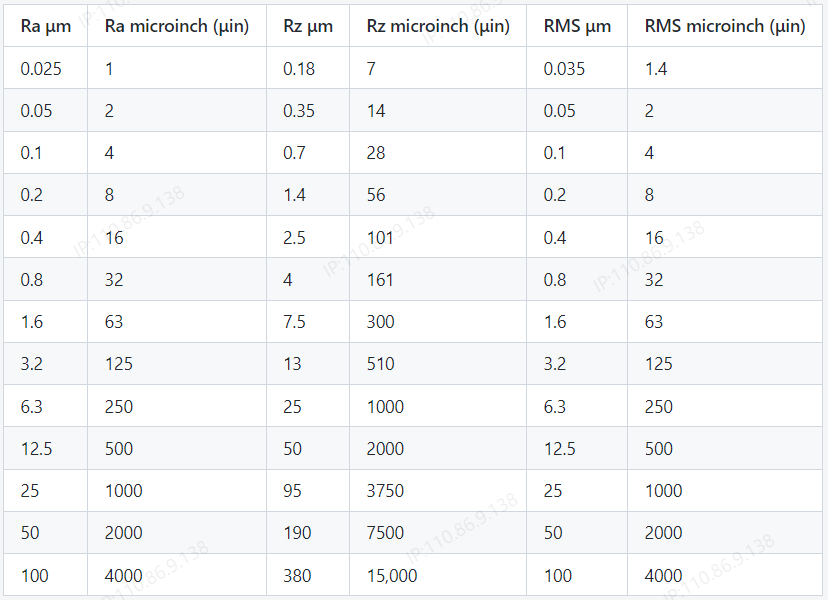

Surface Roughness Conversion Table

Note:

Ra stands for Arithmetic Average Roughness and is measured in μm or μin.

Rz stands for Maximum Height of the Profile and is measured in μm or μin.

RMS stands for Root Mean Square and is measured in μm or μin.

CNCMECHA can produce bespoke and high precision CNC Machined parts, from low volume prototyping to high volume manufacturing. We can produce these parts from plastic and metal materials, including Steel, Aluminium, Stainless Steel, Brass, Copper, Bronze, Titanium, POM, ABS, PP, etc.

We partner with top-quality factories to produce tolerances of ± 0.05 mm or tighter, with one to two and a half weeks lead time for complex projects, quality assurance reports and certificates, and more.

Please CONTACT US to discuss the best materials and surface roughness for your project today or request a 24-hour quote!