When it comes to manufacturing processes, you will find that there are many different methods to choose from, each offering a more efficient and effective way of producing. The most common four processes are CNC machining, die casting, extrusion, and 3D printing are the most popular methods nowadays. In this article, we will compare these processes based on their pros and cons to help you get some ideas.

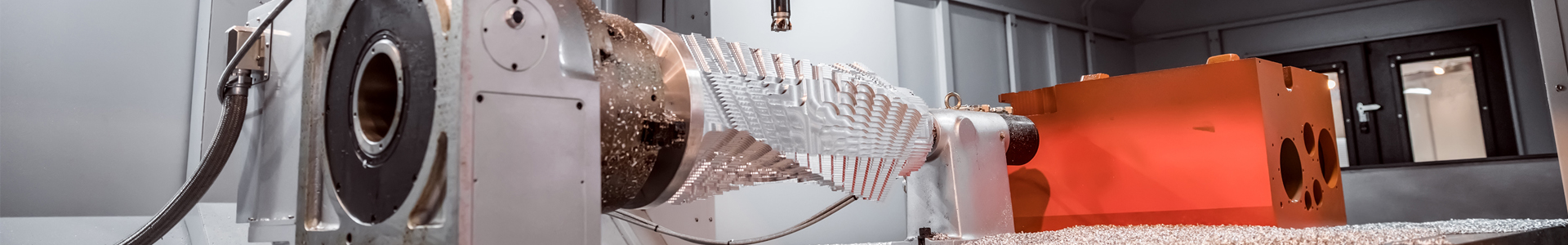

CNC Machining

CNC machining involves using computer-controlled machines such as CNC milling, lathing, laser, EDM, etc. to shape metals, plastics, and other materials into the desired shape. This process is widely used in manufacturing complex parts that require high precision and accuracy.

The advantages of CNC machining:

- High precision: CNC machines can achieve a high level of accuracy and consistency suitable for manufacturing parts with strict tolerance requirements. CNCMECHA is available to make minimum +/-0.01 mm (0.0003 inch) tolerance.

- Versatility: CNC machining can be used to create a variety of parts, from simple to complex shapes. Click HERE to check the projects done by CNC machining.

- Cost-effective: Once machine programming is completed, CNC machining can run continuously, reducing labor costs and increasing productivity.

The disadvantages of CNC machining:

- Limited material selection: CNC machines are typically designed for specific materials, which may not be suitable for all materials.

- High capital cost: Purchasing and maintaining CNC machines can be expensive.

Casting

Casting is a process that involves injecting molten metal into high-pressure molds or dies. The molten metal is then cooled and solidified, forming the final product. Click HERE to check more casting projects.

The advantages of die casting:

- High precision: Die casting can achieve a high level of accuracy suitable for manufacturing complex parts with fine details.

- High strength: The resulting parts have high strength, which can withstand high stresses and loads.

- Cost-effective: Die casting is cost-effective for producing large volumes of parts.

The disadvantages of die casting:

- Limited design flexibility: The mold design may limit the design of the resulting parts.

- Limited material selection: Die casting is typically used for metals and may not be suitable for other materials. Mostly CNCMECHA cast are Aluminum alloy and Stainless steel.

Extrusion

Extrusion is a process that involves pushing materials (such as metal or plastic) through a die to create a specific shape.

The advantages of extrusion:

- High production yield: Extrusion can produce a large number of products quickly and efficiently.

- Low material waste: The process can be designed to minimize material waste.

- Uniformity: Extrusion products have uniform shapes and sizes.

The disadvantages of extrusion:

- Limited design flexibility: The mold design may limit the design of the resulting parts.

- Limited material selection: Extrusion is typically used for metals and plastics and may not be suitable for other materials.

Click link HERE to read more about Aluminum extrusion.

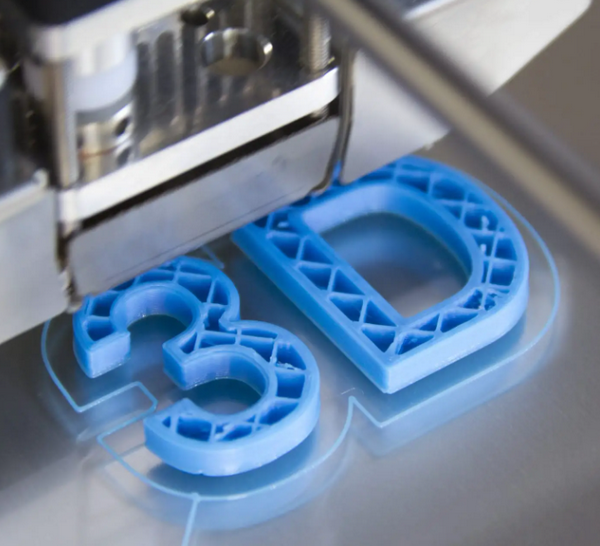

3D Printing

3D printing is an additive manufacturing process that involves creating physical objects by adding layers of material.

The advantages of 3D printing:

- Design flexibility: 3D printing allows for greater design flexibility, creating complex shapes and structures.

- Speed: 3D printing can produce parts quickly and efficiently.

- Low material waste: The process can be designed to minimize material waste.

The disadvantages of 3D printing:

- Limited strength: 3D printed parts are typically not as strong as those produced by other manufacturing processes.

- Limited material selection: 3D printing is typically used for plastics and metals and may not be suitable for other materials.

- Limited scalability: 3D printing is typically best suited for producing a small number of parts.

In conclusion, each manufacturing process has its pros and cons, and the specific process chosen usually depends on the specific requirements of the product being produced. CNC machining is suitable for precise and complex parts, while die casting is ideal for mass production of high strength parts. Extrusion is best for quickly creating uniform parts, while 3D printing is suitable for producing complex, customizable parts.

CNCMECHA can produce bespoke and high precision CNC Machined parts, from low volume prototyping to high volume manufacturing. We can produce these parts from plastic and metal materials, including Steel, Aluminium, Stainless Steel, Brass, Copper, Bronze, Titanium, POM, ABS, PP, etc.

We partner with top-quality factories to produce tolerances of ± 0.05 mm or tighter, with one to two and a half weeks lead time for complex projects, quality assurance reports and certificates, and more.

Please CONTACT US to discuss the best materials and surface roughness for your project today or request a 24-hour quote!