In recent years, there has been a global awareness of environmental protection, and many stringent environmental laws have been promulgated to control toxic substances. Among them, the use of hexavalent chromium has been officially adopted in Europe, the United States, and Japan, and will be banned year by year. In response to this trend, NOF MCAP (Japan), NOF MCNA (USA) and NOF MCEU (France) have jointly developed GEOMET® products with excellent performance and completely chrome-free to meet the environmental protection needs of the world.

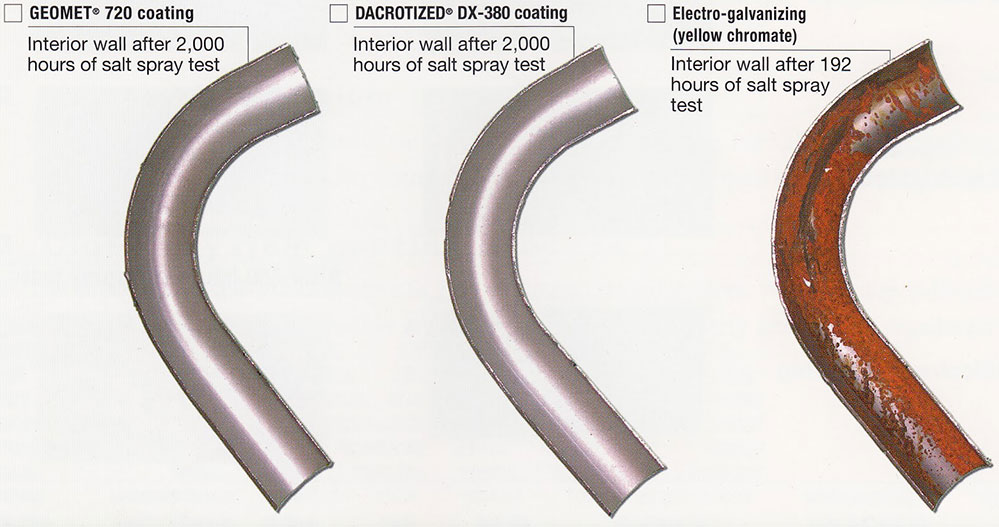

The chrome-free Geomet coating, as an updated product of Dacromet coating, has been first used in automobile manufacturing generally recognized and accepted by the industry. Geomet is more environmentally friendly and has stronger salt spray performance.

The appearance of Geomet coating is matte silver gray, and its luster is slightly darker than that of Dacromet coating. It is an inorganic coating that superimposes ultrafine zinc flakes and aluminum flakes and wraps them in a special binder.

Advantage:

(1) Barrier protection: The treated layer-by-layer zinc flakes and aluminum flakes provide an excellent barrier between the steel substrate and the corrosive medium, preventing the corrosive medium and depolarizer from reaching the substrate.

(2) Electrochemical action: the zinc layer is corroded as a sacrificial anode to protect the steel substrate.

(3) Passivation: The metal oxide produced by passivation slows down the corrosion reaction rate of zinc and steel.

(4) Self-healing effect: When the coating is damaged, zinc oxides and carbonates move to the damaged area of the coating, actively repairing the coating and restoring the protective barrier.

(5) Due to the extremely thin coating - only approx. 8 μm thick, the optimum fit between the bolt and the nut is not compromised at all.

For more surface protection coatings, please read relenvant file below.

![]() Mian Corrosion Types And Surface Protection.pdf

Mian Corrosion Types And Surface Protection.pdf