CNCMECHA

CNCMECHA (Xiamen Huli Xindawei in Chinese) is located in Xiamen City, Fujian Province, Southeast of China. Dedicated in CNC Machining, Aluminium Extruding, Die Casting, Metal Fabrication service who are capable of customizing various kinds of components according to the drawing requirements or based on samples.

We have rich, stable, long term partner factories who are providing stable good quality products with competitive price. Our professional and good service is our strongest strength which helped us won a bunch of customers all over the world. Choose a professional and reliable vendor, to minimize risks and save your time!

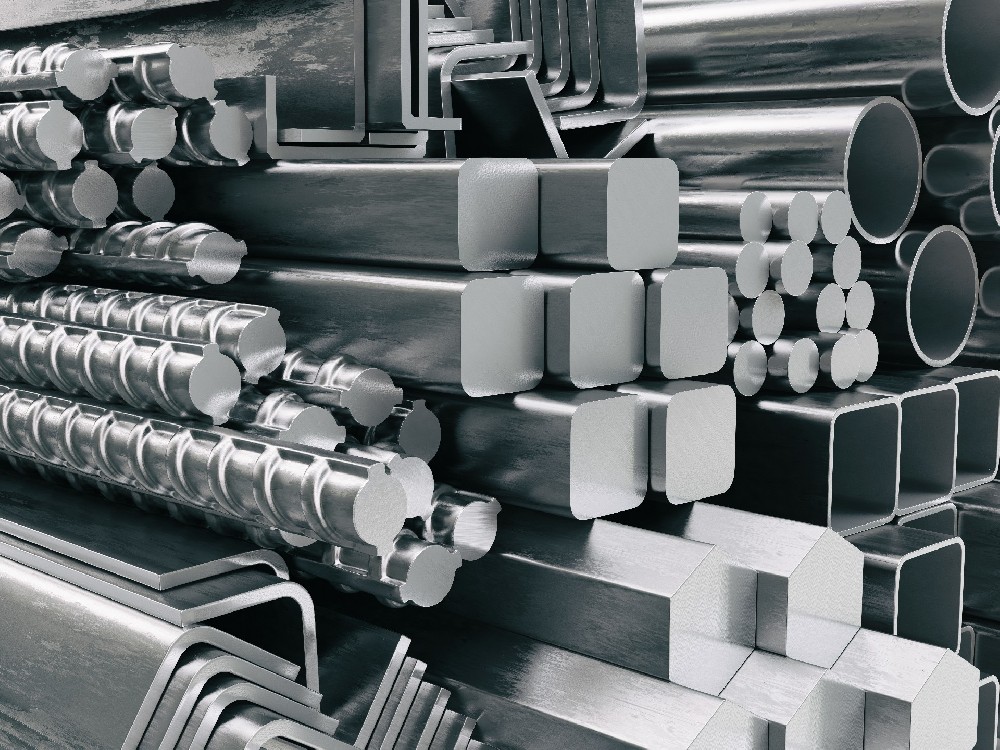

Main service: CNC Machining, Aluminium Extruding, Die casting, Metal fabrication

Material available: Aluminium, Steel, Stainless steel, Brass / copper, Titanium, Plastic, etc.

Main application industry: Machinery, Keyboard Case, Auto, Engine, Motor, etc.

Surface treatments available: sand blasting, anodizing, brushing, polishing, hardening, passivation, zinc-plating, hot-dip galvanizing, electrophoresis, powder coating, etc.

Accuracy: min +/-0.01mm depends on the drawing requirement.

Average lead time: 14 days for sampling, 25-35 days for production.

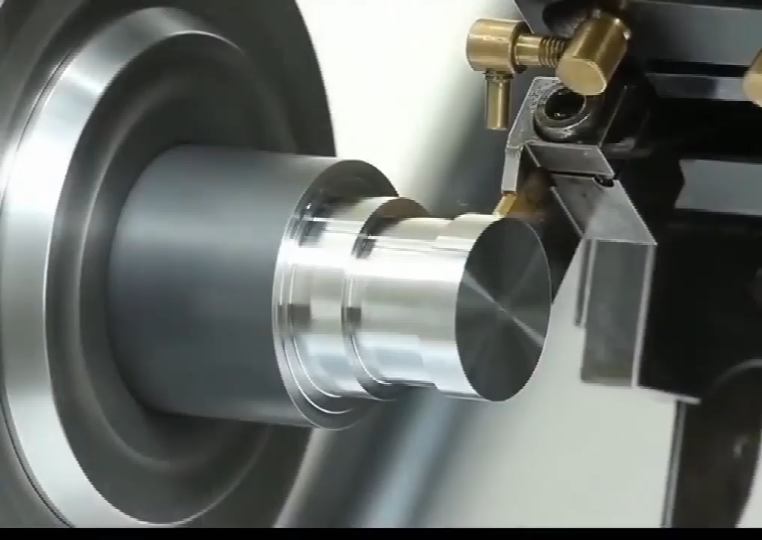

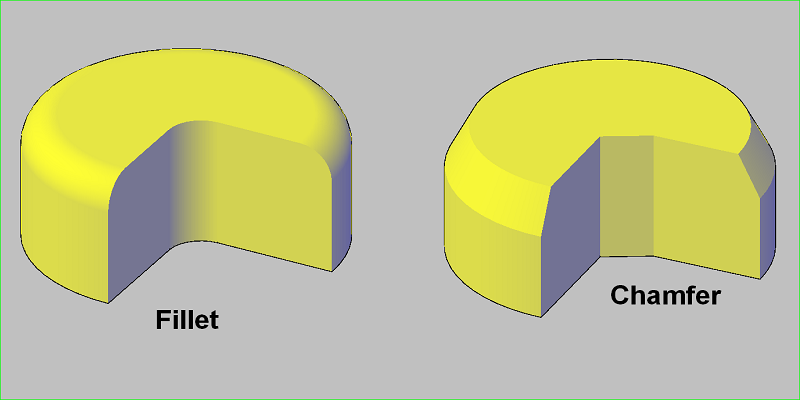

1. CNC Machining: Flexible 3, 4 and 5 axis CNC configurations for precision machined components ensure your design turns out successfully every time. Supports from prototyping to rapid tooling and low volume production benefit customers in time and costs saving on quality control and supplier management, producing parts close to final production, as trials to eliminate production risks.

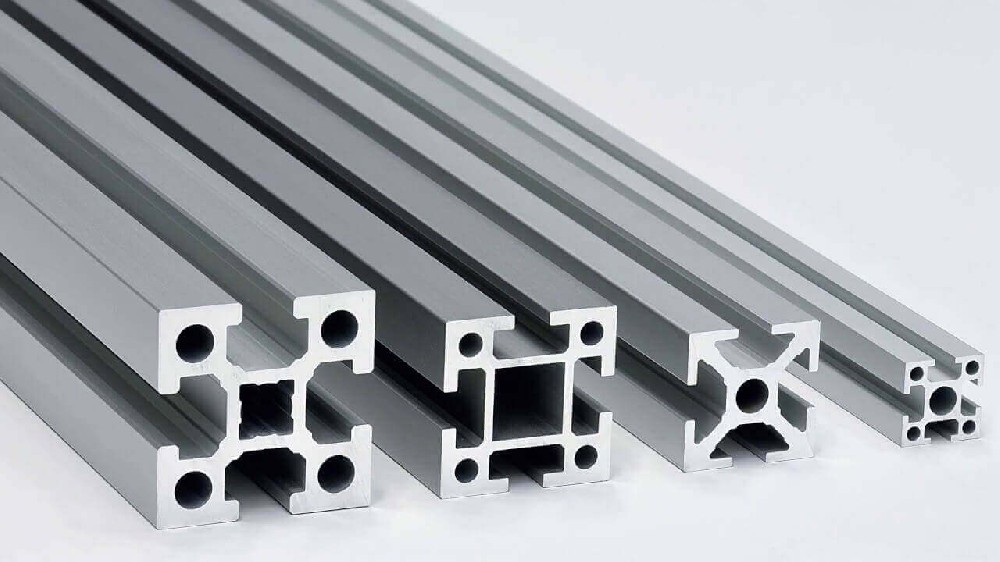

2. Aluminium Extruding: Aluminium extrusion is easier than welding. Construction companies prefer this for several reasons. It is economical as well as helps to fabricate parts with an invariable cross section. Aluminium is a good heat protector and the metal can be easily bonded with adhesive. And above all, aluminum extrusion are cost-effective to fit.

3. Die casting: Die cast manufacturing is one of the most widely used manufacturing techniques. In this process, also known as permanent mold casting, machines or tools are used to create detailed metal molds. After they have been filled with molten metal, the molds are cooled, and the resulting parts are ejected.

Die casters make metal parts by melting and pouring them into a mold. The molds are made from steel or ceramic with cavities that match the shape of the final part. Innovations in die casting have come from all sources, including research institutes, universities, and industry. Often these innovations have also spun off into other sectors, such as high-volume, low-cost production of automotive parts.

4. Custom Mechanical Keyboard Parts

We are serving many famous US and AU mechanical keyboard brands for premium mechanical keyboard parts, such as keyboard cases, weighing plates, keycaps with hi-end quality surface treatment and accuracy.

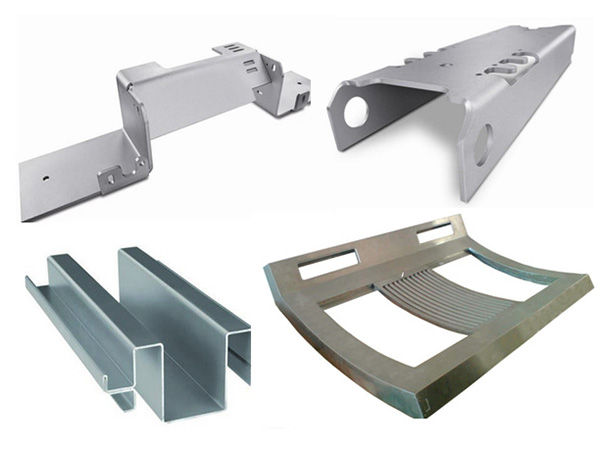

5. Metal Fabrication

Laser cutting, bending, welding is available.

Join us on our journey as we grow larger and larger month by month to offer you good quality products at great prices! Thanks for stopping by!