Introduction:

Aluminum casting is a versatile and widely used manufacturing process for producing complex parts and components with high precision and efficiency. From automotive to aerospace industries, aluminum castings play a crucial role in various applications due to their lightweight, corrosion resistance, and excellent mechanical properties. In this comprehensive guide, we will explore different types of aluminum casting methods, detailing their processes, advantages, and applications.

1. Sand Casting:

Process: Sand casting is one of the oldest and most widely used aluminum casting methods. It involves creating a mold made of compacted sand around a pattern of the desired part. Molten aluminum is then poured into the mold cavity, where it solidifies to form the desired shape. Once cooled, the sand mold is broken away, leaving behind the aluminum casting.

Advantages:

Cost-effective for low to medium production volumes.

Suitable for large and complex parts.

Versatile and adaptable to various shapes and sizes.

Applications:

Engine blocks

Transmission cases

Pump housings

2. Die Casting:

Process: Die casting involves injecting molten aluminum into a steel mold cavity under high pressure. The mold is typically water-cooled to facilitate rapid solidification. Once solidified, the mold opens, and the aluminum casting is ejected. Die casting offers high precision and repeatability, making it ideal for mass production.

Advantages:

High dimensional accuracy and surface finish.

Short cycle times for high-volume production.

Complex shapes and thin-walled sections achievable.

Applications:

Automotive components (e.g., engine parts, wheels)

Electronic enclosures

Consumer appliances

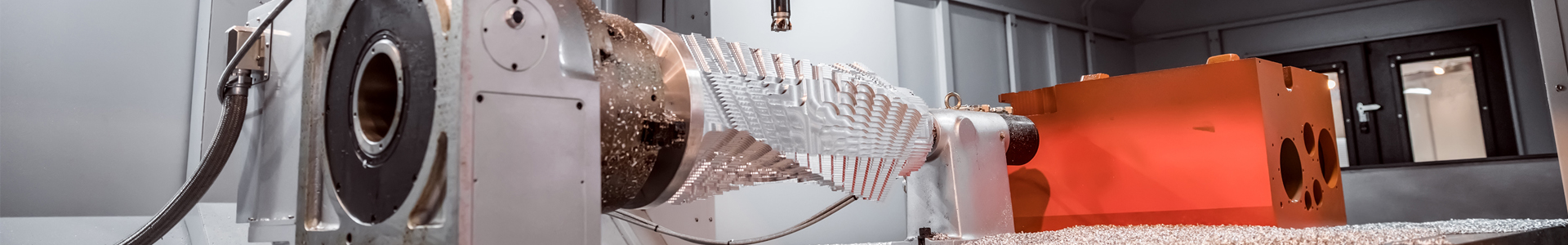

3. Investment Casting:

Process: Also known as lost-wax casting, investment casting involves creating a wax pattern of the desired part, which is then coated with a ceramic shell. The wax is melted out of the shell, leaving a cavity into which molten aluminum is poured. Once solidified, the ceramic shell is broken away, revealing the aluminum casting.

Advantages:

Excellent surface finish and intricate detail reproduction.

Suitable for small to medium-sized parts with complex geometries.

Wide range of alloys applicable.

Applications:

Aerospace components (e.g., turbine blades, fuel nozzles)

Jewelry

Dental prosthetics

4. Permanent Mold Casting:

Process: Permanent mold casting, also known as gravity die casting, involves pouring molten aluminum into a reusable metal mold under gravity. The mold is typically made of steel or cast iron and can withstand multiple casting cycles. Permanent mold casting offers a balance between cost-effectiveness and part quality.

Advantages:

Higher dimensional accuracy and surface finish compared to sand casting.

Suitable for medium to high-volume production.

Longer tool life and lower maintenance costs.

Applications:

Heat sinks

Lighting fixtures

Hydraulic components

Conclusion:

Aluminum casting methods offer a diverse range of options to meet various manufacturing needs, from prototyping to mass production. Each method has its unique advantages and applications, catering to different production volumes, part complexities, and quality requirements. By understanding the characteristics of each casting method, manufacturers can effectively utilize aluminum casting to produce high-quality components across industries, driving innovation and efficiency in the manufacturing sector.