Titanium is a chemical element with the symbol Ti and atomic number 22. It is a lustrous transition metal with a silver color, low density, and high strength. Titanium is highly corrosion-resistant and has a very high melting point, making it useful in a variety of applications.

Strength: Titanium has a high strength-to-weight ratio, meaning it is very strong for its relatively low density. This makes it ideal for applications where strength is essential but weight needs to be minimized.

Corrosion Resistance: Titanium exhibits exceptional corrosion resistance, even in harsh environments such as seawater and acidic or alkaline solutions. This property makes it highly desirable for use in marine, chemical, and industrial applications where corrosion can be a significant concern.

Biocompatibility: Titanium is biocompatible, meaning it is not harmful to living tissues and is well tolerated by the human body. This makes it suitable for medical implants such as artificial joints, dental implants, and surgical instruments.

Lightweight: Despite its strength, titanium is relatively lightweight compared to many other metals, including steel and aluminum. This makes it particularly useful in aerospace and aviation applications where reducing weight is crucial for fuel efficiency and performance.

High Melting Point: Titanium has a very high melting point, exceeding 1,600°C (2,912°F). This property allows it to maintain its structural integrity at high temperatures, making it suitable for use in high-temperature applications such as jet engines and industrial furnaces.

Ductility: Titanium is reasonably ductile, meaning it can be easily formed and machined into various shapes without sacrificing its strength or integrity. This property enhances its versatility in manufacturing processes.

Non-magnetic: Titanium is non-magnetic, which makes it useful in applications where electromagnetic interference must be minimized, such as in electronic devices or MRI machines.

The Common Grades of Titanium

Titanium is available in various grades, each tailored to specific applications based on factors such as strength, corrosion resistance, and temperature tolerance.

| Grade | Properties | Suitable Coatings | Price Range | Typical Applications |

|---|---|---|---|---|

| Grade 1 | Commercially Pure Titanium (CP-1) | None required | Low | Chemical processing equipment, marine components, architectural structures |

| Grade 2 | Commercially Pure Titanium (CP-2) | None required | Moderate | Chemical processing, architecture, medical implants |

| Grade 5 | Titanium Alloy (Ti-6Al-4V) | Anodizing, PVD coatings, DLC coatings | Moderate to High | Aerospace components, marine hardware, high-performance sports equipment |

| Grade 7 | Titanium Alloy (Ti-0.15Pd) | Anodizing, PVD coatings, Electroless nickel plating | Moderate to High | Chemical processing equipment, desalination plants, marine components |

| Grade 12 | Titanium Alloy (Ti-0.3Mo-0.8Ni) | Anodizing, PVD coatings, Electroless nickel plating | Moderate to High | Chemical processing, seawater applications, hydrocarbon processing |

| Grade 23 | Medical-Grade Titanium Alloy (Ti-6Al-4V ELI) | None required | High | Medical implants, surgical instruments, biomedical devices |

The Limitations of Titanium

| Limitation | Explanation |

|---|---|

| High Cost | Titanium is relatively expensive compared to other metals such as steel and aluminum, primarily due to the costs associated with extraction, processing, and fabrication. |

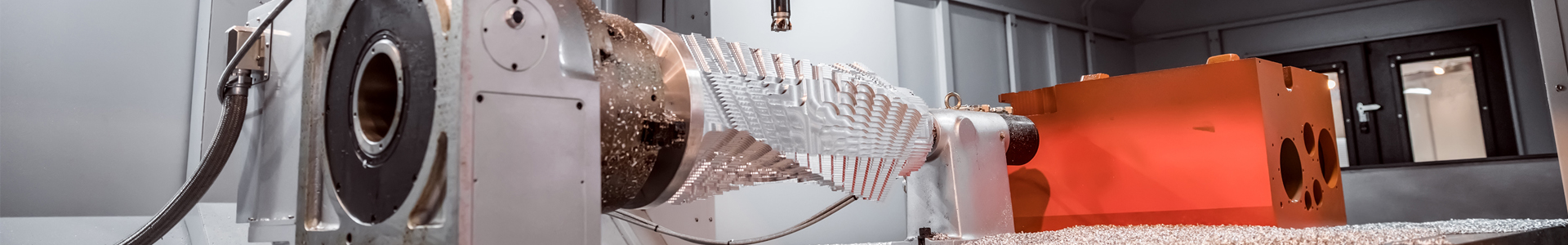

| Machining Challenges | Titanium's high strength and low thermal conductivity can make it challenging to machine, resulting in increased tool wear, slower cutting speeds, and higher machining costs. |

| Reactivity with Certain Elements and Environments | Titanium can react with certain elements and environments, leading to issues such as embrittlement, hydrogen absorption, and contamination in specific applications. |

| Limited Availability of Specialized Alloys | Some specialized titanium alloys may have limited availability or may be more difficult to procure compared to more commonly used grades, affecting supply chain reliability. |

| Sensitivity to Hydrogen Uptake and Embrittlement | Titanium can absorb hydrogen, which may cause embrittlement and reduced mechanical properties in certain conditions, posing challenges in hydrogen-rich environments. |

| Challenges in Joining and Welding | Titanium's high reactivity and susceptibility to contamination can make welding and joining processes challenging, requiring specialized techniques and equipment. |

| Low Thermal Conductivity | Titanium has lower thermal conductivity compared to some other metals, which may limit its suitability for certain high-temperature applications requiring efficient heat transfer. |

Comparison of Titanium vs. Aluminum

| Property | Titanium | Aluminum |

|---|---|---|

| Density (g/cm³) | Approximately 4.5 | Approximately 2.7 |

| Strength-to-Weight Ratio | High | Moderate |

| Melting Point (°C) | ~1,668°C | ~660°C |

| Corrosion Resistance | Excellent | Moderate to Good |

| Cost | Higher cost | Lower cost |

| Machinability | More challenging | Easier |

| Thermal Conductivity (W/(m·K)) | ~21 | ~237 |

| Electrical Conductivity (%) | ~3.1 | ~61 |

| Ductility (%) | ~15 | ~10-20 |

| Availability | Limited | Abundant |

| Applications | Aerospace, Medical, Chemical Processing | Automotive, Construction, Packaging |

CNCMECHA provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.