What is CNC milling?

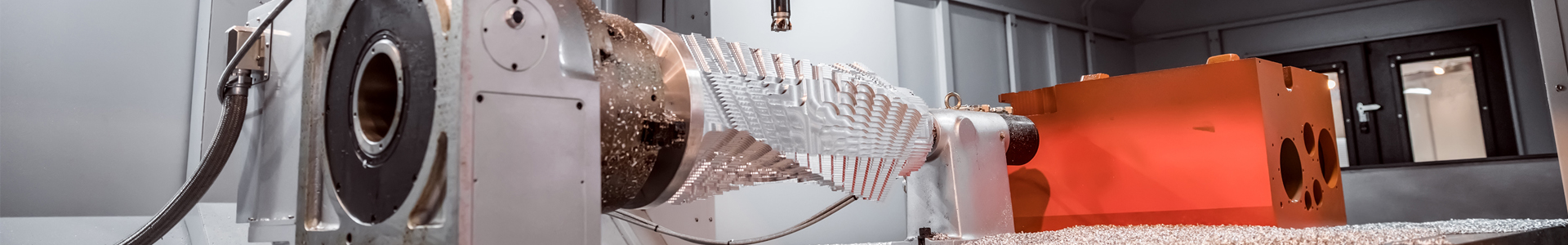

Although the methods of removing materials are different, first of all, CNC drilling and milling machines and CNC lathes remove materials separately to produce a part. A machining center usually combines two methods and multiple tools on one machine. All of these have multi-axis motion function to guide the cutting tool around and through the workpiece to create the exact shape required.

The basic difference between the two methods is that the milling machine uses a rotating tool to cut the workpiece, while the lathe uses a rotating workpiece, and the meshing is completed by the tool.

How does CNC milling work?

Before the introduction of computer numerical control (CNC), milling machines and lathes were operated manually. As the name implies, CNC automates this process to make it more accurate, reliable and fast.

Now, a trained operator programs the G code (representing geometric code) into the machine, usually through software. Each of these controlled milling machines controls the stroke and speed so that it can drill, cut and shape materials to meet the specified dimensions.

There are many different types of CNC milling machines. The most common is the 3-axis machine tool, which moves on the X, Y and Z axes to provide tools for 3D manufacturing. Three-axis machine tools can allow entry from multiple angles by rotating and resetting the workpiece, thus producing more complex features.

On a five-axis machine tool, this ability is optimized by adding two directions of motion, namely, rotation around the X axis and the Y axis. It is an ideal choice for producing complex and precise parts. However, the disadvantage is that using this technology will break your budget because complexity increases costs. Believe it or not, you can define any 3D geometry through five motion axes. However, it is unrealistic to hold the workpiece and rotate freely in all directions. This will be a machine with 6, 7 or even 12 axes. However, unless you need extremely complex parts, you are highly unlikely to need this kind of machine -- because the investment is huge, so is the size of the machine!

What is the next step of NC machining?

As you can see, the development of more and more complex CNC milling machines requires more and more professional knowledge to operate, which requires a lot of time. Even if you outsource CNC processing, the cost of this complexity will be higher, because professional manufacturers must recover their investment. If you have an extremely complex part that requires incredible precision and requires a lot of use, you may be able to prove that the investment is reasonable. For most jobs, 3-axis or 5-axis machining is more than enough.

After all, there is always more than one way to solve the problem -- for example, in general, it is much better and cheaper to design two or more parts that are not too complex, and then use bolts, welding or connecting them as part of the secondary assembly process than to try to process an extremely complex single part.

So why do so many people focus on developing new and expensive machines, while the profits generated by these machines are getting smaller and smaller? This is a bit like Microsoft's office. Most of us use Word, but in fact we may only use 20% of the content it provides. However, Microsoft continues to add new features, most of which we may never need, use or even know.

Instead of making smaller and smaller incremental improvements to the process, we think it is better to improve the process itself. This is where we can make real profits.

Process automation

Let's go back to the beginning and study the process of making a part.

It all starts with the designer designing the parts or components needed on his CAD system. Generally, an experienced person programs G code for computer-aided manufacturing (CAM).

However, once the design is in place, why add another step? The good news is that you can use many CAD software packages to convert your CAD into G code -- but we need to go back one step.

Once you have designed your parts, how do you know that they can be manufactured by CNC machining and meet your requirements? Your CAD should be a digital line connecting everything, with little or no human intervention.

After all, with Industry 4.0, we should all live in an interconnected world. Most of the work of NC machining still depends on experienced machinists. When you send your design, there is usually a person to check whether it can be made with known technology. If not, we need to tell you so that you can redesign or optimize the design.

At Proteabs, we have automated this process. Once you send your CAD data, our software will check its feasibility and generate a quotation. If the proposed modifications are necessary, they will be displayed to your CAD in the feasibility report automatically generated by the software. Once you agree to design and manufacture, our software will create the code required for processing according to the provisions in the quotation.

Faster and more cost-effective

This makes the process faster and more cost-effective, which can have a real impact on small and medium-sized work or prototype design and testing of new components.

Because of the automation, this service is the same for everyone, regardless of the size of the project. It is understandable that traditional engineering companies will give priority to those projects that can make them more money - whether due to the scale of the work or the complexity of the required parts - which depends on their ability.

Process automation makes the competitive environment more fair. Therefore, you can still benefit from the same speed and service quality for prototyping or requiring small or medium quantities of parts.

Because all this information is generated and collected from the beginning, we can cut and transport customized CNC milling plastic and metal parts in just 24 hours. If you are not in a hurry, you can choose a later delivery date and reduce your costs - so you can even set your own terms.

This process starts with your CAD, which means that after you design your parts, we have a digital line that we can use in the whole NC machining process - from your computer to delivery.

Automation is not only a problem of CNC milling and turning. It includes everything from design. This is the future of CNC milling. This is the real Industry 4.0 action.