01. Performance requirements of CNC tool.

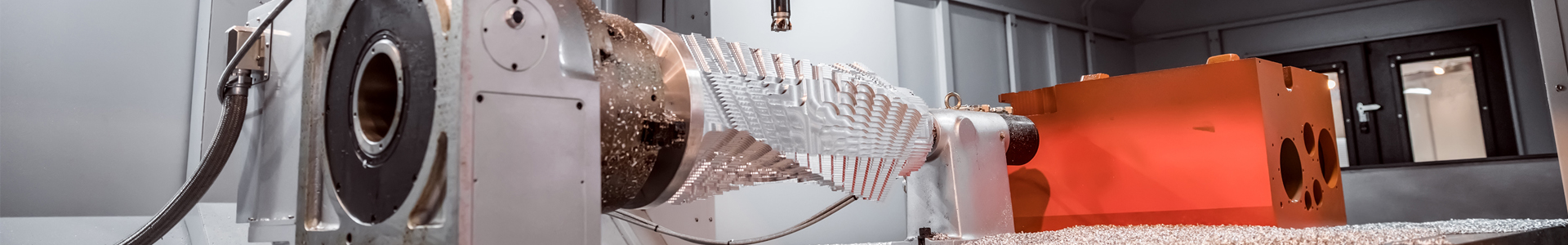

Because CNC machine tools have the characteristics of high machining accuracy, high machining efficiency, centralized machining process, short clamping time of parts, etc., higher requirements are put forward for the use of CNC tools.

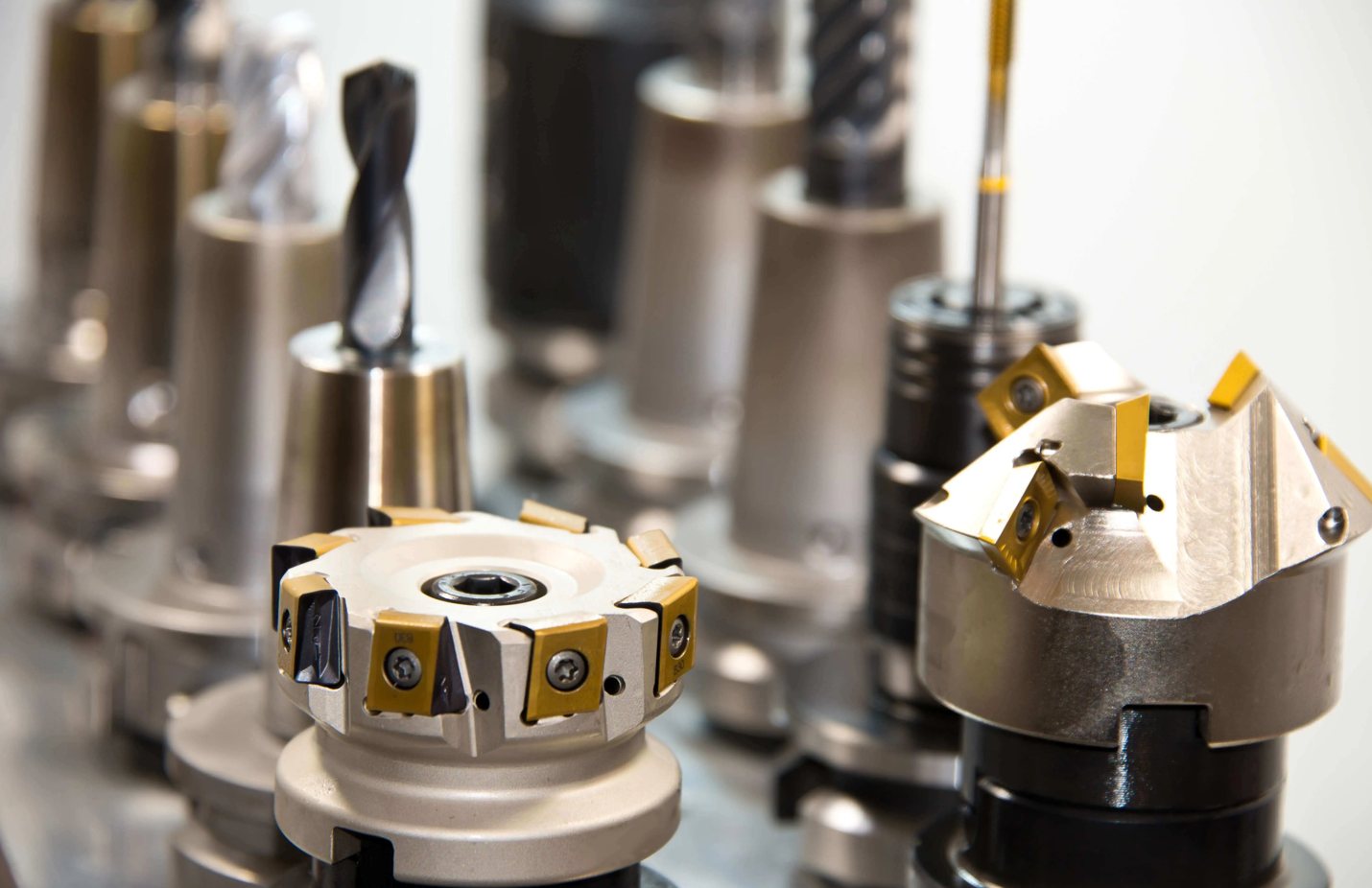

When selecting CNC tools, standard tools should be taken as the main tool first, and various high-efficiency composite tools and special tools can be selected as required. When selecting standard CNC tools, various advanced tools should be selected as far as possible according to the actual situation (such as indexable tools, solid carbide tools, ceramic tools, etc.).

When selecting CNC machine tools to handle tools, the following aspects must also be considered:

1. Model, specification and accuracy grade of CNC tools.

The model, specification and accuracy grade of the NC tool shall meet the processing requirements, and the tool material shall be compatible with the workpiece material.

2. Good cutting performance.

In order to adapt to rough machining and machine tool processing, large back cutting and high feed can be used, and can withstand high speed cutting and strong cutting performance. At the same time, the cutting performance and tool life of the same batch of tools must be stable, so that the tools can be changed according to the difference of tool life, or the tool life can be managed through the CNC system.

3. High accuracy.

In order to meet the requirements of high-precision CNC machining and automatic tool replacement, high-precision is required, such as the radial dimension accuracy of some solid end mills.

4. High reliability.

In order to ensure that the tool will not be accidentally damaged and there will be no potential defects in CNC machining, the tool and accessories must be reliable and applicable.

5. High durability.

The durability of tools used in CNC machining is higher than that of tools used in conventional machine tool machining in rough machining and finish machining.

In CNC machining, blade cutting and blade removal cannot be handled as usual machine tools, and can be handled manually in time. The blade is easy to pack tools and workpieces. It damaged the tool, scratched the machined surface of the workpiece, and caused further injuries and equipment accidents. Due to the quality and safe operation of the machine, the tool fracture and the retraction performance of the blade are good.

02. How to select a tool?

Because the spindle speed and range of CNC machine tools are much higher than that of ordinary machine tools, and the output power of the spindle is also large, higher requirements are put forward for CNC machining tools including high precision, high strength, high rigidity, high durability, high durability, dimensional stability, and easy setting and adjustment compared with previous machining methods. This requires the proper tool structure, standardization and the concatenation of geometric parameters. CNC tool is one of the preconditions to improve the machining efficiency. Its selection depends on the shape of the parts to be processed, the state of the material, the rigidity of the fixture, and the tool selected by the machine tool.

Please consider the following:

1. Select tools according to the cutting performance of parts and materials.

For rotating or grinding high-strength steel, titanium alloy and stainless steel parts, it is recommended to use indexable carbide tools with better wear resistance.

2. Select the tool according to the part processing stage.

That is to say, in the rough machining stage, the rigidity is mainly reduced by removing the finish machining. The purpose is to select more accurate tools. In the semi-finish machining process, the machining accuracy and product quality of parts are mainly guaranteed, but the durability of higher performance and high-precision tools is guaranteed. The tool accuracy used in the rough machining stage is low. In addition, the precision of the tools used in the finishing table is very high.

If the same tool is selected for rough machining and finish machining, most of the tool edges removed from finish machining will be slightly worn and will be worn due to coating wear. Therefore, it is recommended to select the tool removed from finish machining during rough machining. Continuous use will affect finishing. The processing quality has little effect on the rough surface treatment.

3. Select tools and geometric parameters according to the characteristics of the processing area.

If the structure of the part is acceptable, the tool with large diameter and small aspect ratio must select the edge of the ultra-center milling tool to cut the thin-walled and ultra-thin pendulum parts, and must have sufficient centripetal angle to reduce the cutting force of the tool and cutting parts. For processing parts made of soft materials such as aluminum or copper, select the end milling cutter with slightly larger angle, which will not exceed 4 teeth.