CNC machining, also known as Computer Numerical Control machining, is a manufacturing process that involves the use of computer-controlled machines to produce parts and components with high precision and accuracy. This process is widely used in various industries, including automotive, aerospace, medical, and electronics.

CNC machining, also known as Computer Numerical Control machining, is a manufacturing process that involves the use of computer-controlled machines to produce parts and components with high precision and accuracy. This process is widely used in various industries, including automotive, aerospace, medical, and electronics.

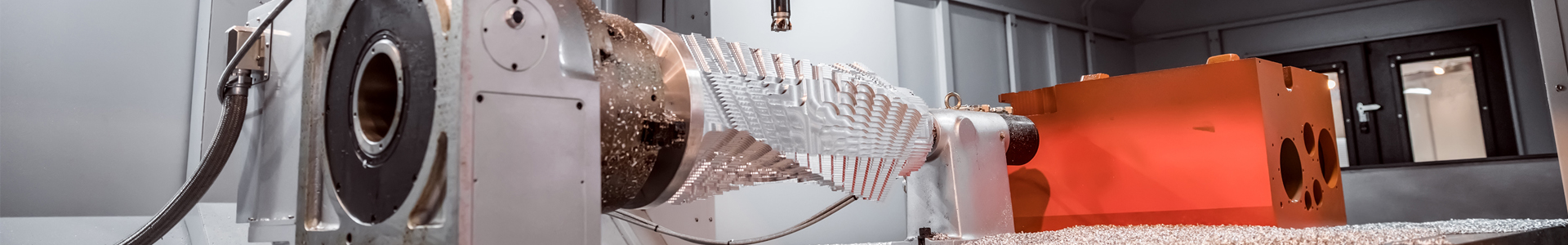

CNC machines operate by using computer programs that control the movement and operation of the cutting tools. These tools can be milling machines, lathes, routers, or grinders, and they can work with a wide range of materials, such as metals, plastics, and composites.

One of the key advantages of CNC machining is its ability to produce complex shapes and geometries that would be difficult or impossible to achieve with conventional machining methods. This is because CNC machines can operate with high precision and repeatability, allowing for intricate designs and features to be machined with ease.

Another advantage of CNC machining is its speed and efficiency. Once the program is set up and the machine is running, parts can be produced quickly and with minimal human intervention. This not only saves time but also reduces the risk of errors and inconsistencies that can occur with manual machining.

CNC machining also offers a high level of flexibility, as the same machine can be used to produce different parts and components by simply changing the program. This makes it ideal for small-scale production runs and prototyping, where the ability to quickly switch between different designs and products is crucial.

However, CNC machining also has some limitations and drawbacks. One of the main disadvantages is the high cost of the machines and the programming software, which can make it prohibitive for small businesses or individuals. Additionally, CNC machines require skilled operators who are knowledgeable in programming and operating the machines, which can also add to the cost.

Overall, CNC machining is a powerful manufacturing process that offers numerous benefits in terms of precision, speed, and flexibility. While it may not be suitable for all applications, it has become an indispensable tool for many industries, and its use is likely to continue to grow in the future.