Aluminium

Aluminium is the most important industrially used metal after steel today with applications in almost all fields and all areas of everyday life due to its lightweight, high strength, and recyclability.

Aluminium has been described as “the material of opportunity” and is the fastest-growing metal today due to its unique combination of properties – high strength and low weight, good electrical and thermal conductivity, excellent formability, good resistance to corrosion, and attractive surface finish – which means it can be used practically in all design contexts and product applications.

Aluminium is extracted from its oxide “alumina” by the Hall-Heroult process in smelters. Alumina is extracted from bauxite by the Bayer process in the Alumina refinery.

Aluminium can be recycled and used time and time again, whilst using only a fraction of the energy required for its primary production.

Advantages of Aluminium Extruded Products: The benefits of aluminium products are diverse.

1. Lightweight: The weight of aluminium is one-third of iron, steel, copper, or brass. It is easier to carry and handle metal.

2. Strength: Aluminium products and aluminium extrusion profiles can be made as strong as needed.

3. Strength and weight ratio: The united property of strength and lightness in aluminium extruded products makes it a key component of several industry-based applications.

4. Corrosion resistant: The metal has a natural protective coating against environmental, chemical, and physical corrosive materials.

5. Heat transmission: Aluminium is a better conductor of heat on a cost and weight basis.

6. Electric transmission: Aluminium is a better conductor than copper per unit weight. It is commonly used for power consumption.

7. Wide approval: Aluminium extruded products are largely used in the food packaging and chemical industry.

8. Easy to manufacture: The metal, by using conventional methods, can be given any shape.

9. Easy for assembly design: Aluminium extruded products are easy to assembly design.

10. Ability to join: Methods like welding, soldering, and brazing are used to join extrusions.

11. Superior quality: Aluminium extruded products guarantee trustworthiness and uniformity in quality.

Aluminium alloys and tempers

Emirates Extrusion produces most of the customer requirements in its facilities using alloys 6061 and 6063 with T4, T5, and T6 tempers.

6061 is a precipitation-hardening aluminium alloy, containing magnesium and silicon as its major alloying elements. It has good mechanical properties and exhibits good weldability. It is one of the most common alloys of aluminium for general-purpose use.

6063 is an aluminium alloy, with magnesium and silicon as the alloying elements. It has generally good mechanical properties and is heat treatable and weldable. 6063 is mostly used in extruded shapes for architecture, particularly window frames, door frames, and roofs. It is typically produced with very smooth surfaces fit for anodizing.

T4 : Solution heat treated and naturally aged to substantially stable condition

T5 : Cooled from an elevated temperature and then artificially age hardened

T6 : Solution heat-treated and artificially age hardened

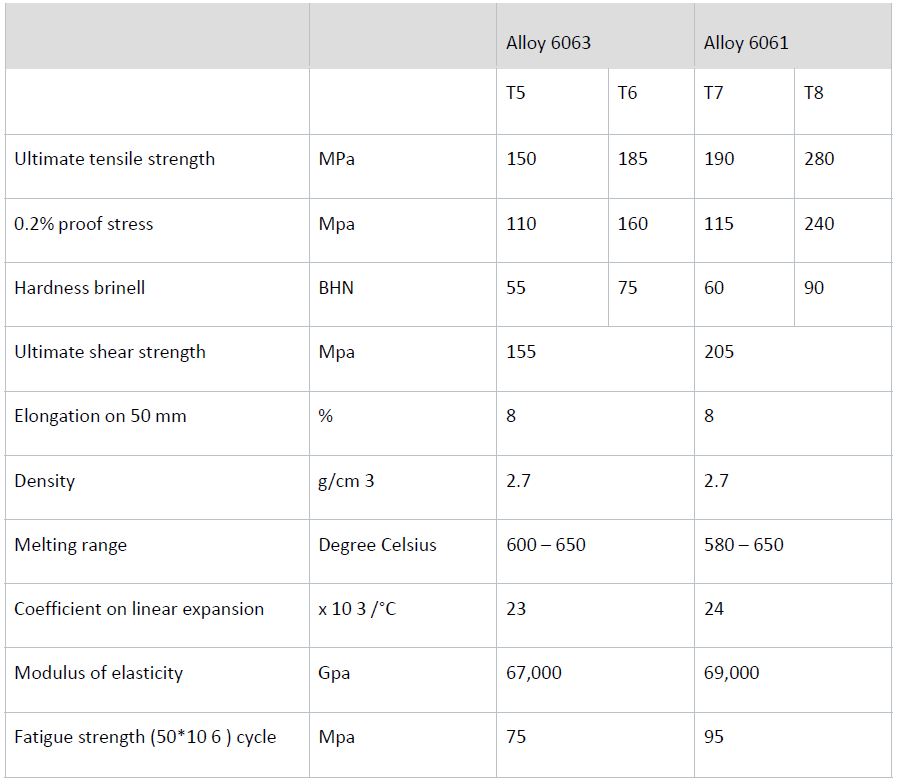

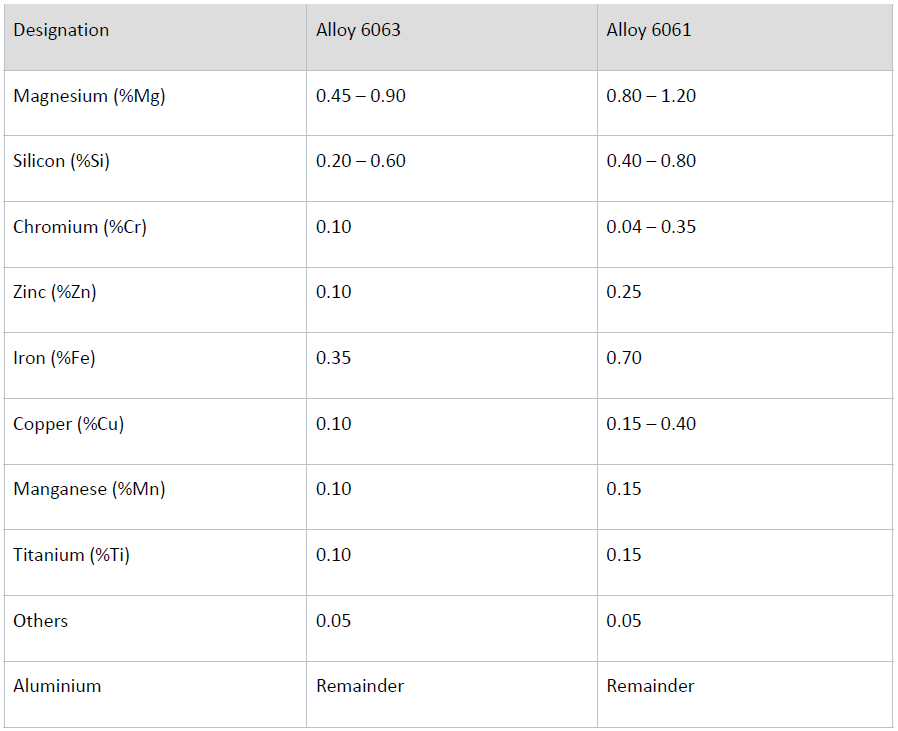

Chemical Composition of Alloys 6063 and 6061, Tempers T5 & T6

Mechanical properties of Alloys 6063 and 6061, Tempers T5 & T6